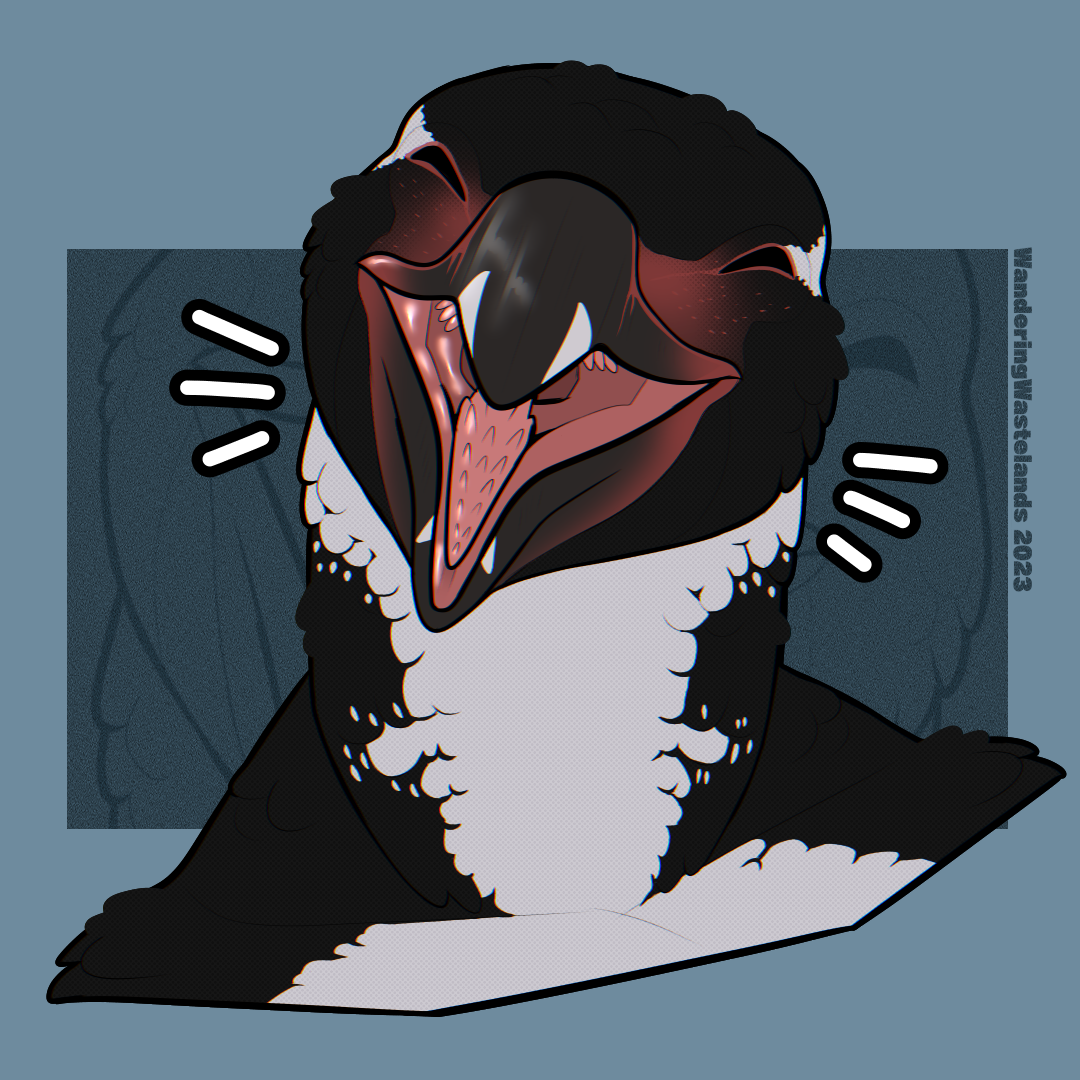

I have always wanted to try printing larger, using a bigger nozzle - just got around to swapping to a .6mm in my MK3S+. Printed a gift for a childhood friend. 300% size. Took just under 10 hrs. With the slicer settings on .4mm it was over 17hrs.

When it works, it’s pretty great. I’ve got a weird overextrusion issue to fix on my MK3S+ with the 0.6 nozzle, but the prints themselves are tougher and faster.

Did you play around with different filament settings or presets? Most importantly extrusion multiplier?

Measuring the filament might be a good idea too, maybe slight differences are becoming visual with a bigger nozzle

Thanks for the ideas, yeah I’ve tried playing around with the presets and such, and I’m fairly certain the filament itself is good, matterhackers pro PETG.

When I have a moment I’ll be trying to make an extrusion tower to test settings.

PETG is very leaky. It’s not a big deal with 0.4, but becomes a pain with 0.6. Try to set a higher printing speed.

I’ve been using 0.6 for some time, I normally do functional prints. It is a good compromise between speed and quality.

Ever since Arachne came out .4 became obsolete for me. If you play with the settings right a .6 can produce nearly the same small details while being way faster for infill etc.

Can I ask what settings you had to hone in?

I lowered minimum wall width and wall transition length.

Like many others on here, my stock is now 0.6mm

I’ve also tried a 0.8mm which is amazing haha. Though it definitely has it’s limitations, so I usually just stick with 0.6mm

How did that print so well without any supports?

That is a very good question. There aren’t any insane overhangs, just a few tricky spots. I had print he same thing smaller, so I knew it would be okay. I think the file actually mentioned in the notes that you COULD print it without support.

I was shocked too at first, but then i realized the same thing, i don’t see anything problematic, what a great model

I had to dig to find where I got the model from. I suppose I should add the link in case anybody wants to give them kudos or print it for themselves.

It was created by Rocket Pig Games: Printables link

I also use .6 as my standard nozzle. Since the stuff I print is usually custom brackets and cases, a bigger nozzle would be even more ideal. The problem is my stock heating can’t keep up with anything larger than a .6

What printer and hot end?

It’s an ender 3 pro with the stock hot end, but it’s also running klipper and prints at 60mm/s

I have the same setup and with a bigger nozzle I found it useful to use auto speed and max volumetric flow, rather than speed. I found the hotend reaches its flow capacity before speed becomes an issue.

What slicer are you using? I’m using Cura and I vaguely remember that being the reason why I didn’t do that.

I’ve been using super slicer, but it’s a fork of prusa slicer and I’m pretty sure the auto speed feature is a prusa slicer thing.